Thermal Energy Storage tank (TES tank)

for Cooling or Heating

TES for cooling

A thermal energy storage tank (TES tank) in cooling/HVAC systems is used to store “cooling energy” usually in the form of chilled water or ice so the building can meet cooling loads more efficiently, reduce operating costs, and improve system reliability.

Below is a clear, practical explanation:

What Is a TES tank

A TES tank is a large insulated vessel that stores cooling energy produced during off-peak hours (typically night). This stored energy is then used during the day when cooling demand and electricity costs are higher.

It is most common in:

District cooling systems

High-rise buildings

Hospitals and airports

Large commercial/industrial facilities

Types of Cooling Thermal Storage:

A) Chilled Water Storage

A large tank filled with chilled water (typically 4–6 °C).

At night, chillers operate to cool the water and “charge” the tank.

During the day, the tank discharges this cold water to the building.

Pros

✔ Simple design

✔ No special heat exchangers

✔ Good for large capacity

Cons

✘ Large tank size

✘ Needs good stratification (temperature layers)

B) Ice Storage

Ice is created at night and melted during the day to supply cooling.

Two main technologies:

Ice-on-coil

Ice harvester

Pros

✔ Much smaller footprint than chilled water

✔ Very high energy storage density

✔ Takes advantage of low night electricity tariffs

Cons

✘ Requires low-temperature chillers (-5 to -7 °C)

✘ More complex controls

Benefits:

Operational benefits

Reduces peak daytime electricity consumption

Smaller chiller size (lower capital cost)

Improves chiller efficiency (night ambient temperatures are cooler)

Adds redundancy/back-up cooling

Financial benefits

Uses low-tariff night electricity

Reduces demand charges by shifting daytime load

In district cooling, reduces plant size and improves efficiency

Environmental benefits

Less stress on electrical grids

Lower CO₂ emissions (if grid is cleaner at night)

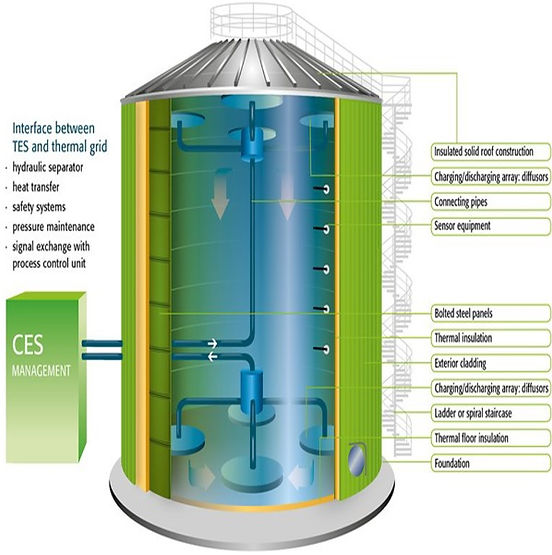

How a TES Tank Works in Chilled Water Systems

Night (Charging Mode):

1. Chillers cool water down to ~4–5 °C.

2. Cold water enters the bottom of the tank.

3. Warm return water exits from the top.

4. Tank develops stratification (cold at bottom, warm at top).

Day (Discharging Mode):

1. Warm return water enters the top of the tank.

2. Cold water exits the bottom to the cooling coils.

3. Tank provides chilled water and reduces chiller operation.

Stratification is critical → The tank must maintain clear layers of cold and warm water without mixing.

Typical Applications

Shopping malls

Airports

Hospitals

District cooling plants

University campuses

Commercial towers

Data centers .

High-rise commercial buildings

Hotels and resorts

Design Features of a TES Tank

Internal diffuser ports to maintain stratification

Insulation (to minimise thermal loss)

Large diameter/height ratiod epending on flow stability

Temperature sensors to track stratification layer

Level indicators

Vortex-breakers

Access hatches

Typical Temperatures

Chilled Water Storage: 4–12 °C (ΔT = 6–8 °C)

Ice Storage: Uses glycol or brine, supply around -5 to -7 °C

Control Strategies

Full storage: TES covers almost all daytime load

Partial storage: TES supports peak hours only

Load shifting: Uses TES to reduce electricity demand

Demand limiting: Keeps plant within energy limits

A thermal energy storage (TES) tank is an innovative solution designed to store thermal energy. This technology enhances energy efficiency by you to utilize stored chilled (or hot) water during peak demand times, reducing on additional energy sources. Ideal for both residential and commercial applications, a TES tank can help lower energy costs and promote sustainable practices. Consider integrating a thermal energy storage into your system for a more efficient energy management strategy.

TES for heatling

Thermal Energy Storage (TES) tanks can also be used for heating, not just cooling.

In heating applications, they store hot water or thermal energy to reduce boiler load, stabilize system operation, and shift energy use to off-peak hours. TES Tanks for Heating (Hot Water Thermal Storage)

What Is a Heating TES Tank

A heating TES tank is a large insulated vessel designed to store hot water (typically 60–95°C depending on system type).

It works by charging the tank when heat is available, and discharging it when heating demand increases.

Used in:

District heating networks

Large commercial buildings

Hospitals

Industrial process heating

Systems using heat pumps or boilers

Benefits

Operational Benefits

Reduces boiler cycling (improves efficiency and lifespan)

Provides backup heating capacity

Balances heat pump load

Smooths out peak heating demand

Allows smaller boilers/heat pumps to be installed

Financial Benefits

Use lower-tariff electricity for heat pumps at night

Avoid peak-time gas charges

Reduce size/cost of heating equipment

Environmental Benefits

Works well with renewable energy:

Solar thermal

Heat pumps

CHP systems

Reduces emissions

Improves overall system efficiency

Types of Heating TES Systems

A) Hot Water Storage (Most Common)

Stores hot water at 60–95°C

Stratified tanks to keep hot and cold layers separate

Used heavily in district heating and heat pump systems

Advantages:

Simple

Long lifespan

Low maintenance

Disadvantages:

Large volume required

Heat loss over long periods

B) High-Temperature Storage (Pressurized Water)

Stores water at 120–180°C under pressure

Used for industrial heating and CHP systems

C) Phase Change Material (PCM) Storage

Uses salts or waxes that melt/solidify

High energy density

Smaller tank sizes

D) Molten Salt Storage (Rare for buildings)

Used for large renewable energy plants

Operates at 250–575°C

TES Tank Components for Heating

Insulation (rockwool, PU foam, PIR panels)

Diffusers to keep water layers stratified

Level sensors

Thermocouples

Manholes

Anti-vortex devices

Anti-corrosion lining (epoxy)

Operating Temperatures

System Type | Typical TES Temperature

Building Heating | 60–75°C

District Heating | 80–100°C

Heat Pumps | 45–65°C

Industrial / CHP | 120–180°C (pressurized)

Typical Applications

District Heating

Stores heat from boilers, CHP, or renewable sources.

Heat Pump + TES

TES stores heat produced during low-tariff periods.

CHP (Combined Heat and Power)

Stores waste heat from engines or turbines.

Solar Thermal + TES

Stores solar heat for night-time heating.

Charging mode/

period

Discharging mode/

period